People utilize oxygen generators as key gas production plants to extract pure oxygen from the atmosphere. The wide range of applications of this technology are in the fields of medicine, industry, metallurgy, food processing and environmental protection. This article will take an in-depth look at how do oxygen generators work and describe its applications in different fields.

What is an Oxygen Generator

Oxygen generator is a kind of machine that can make oxygen, which utilizes air separation technology to extract oxygen from air, all also known as air separation equipment.

According to the working principle, it can be divided into: PSA Oxygen Generator, Cryogenic Oxygen Generator, Electrolyzed Water Oxygen Generator, Oxygen Enriched Membrane Oxygen Generator.

According to the application scenario, they can be divided into: industrial oxygen generator, household oxygen generator, medical oxygen generator.

Oxygen Generator vs. Oxygen Concentrator

We use oxygen generators, a kind of large-scale industrial equipment, primarily in medical facilities, oxygen stations, and industrial applications that require substantial amounts of oxygen. Oxygen concentrators, are small, convenient devices designed for personal use, often for home healthcare, especially for people with respiratory conditions or those who need supplemental oxygen.

How Does an Oxygen Generator Work

Air consists mainly of nitrogen (about 78%) and oxygen (about 21%), with small amounts of other gases also included. The core principle of an oxygen generator is based on the difference between the molecular size and molecular weight of the nitrogen and oxygen molecules in the atmosphere to obtain a purer form of oxygen, usually with a purity of over 90%. This article focuses on how PSA oxygen generators work.

PSA oxygen generator

We operate PSA oxygen generating equipment, also known as variable pressure adsorption oxygen generating equipment, to obtain higher purity oxygen (93% ± 2). At normal temperature and pressure, we use the PSA special molecular sieve to selectively adsorb nitrogen, carbon dioxide, and water vapor, which are impurities in the air. Our main working principle involves two molecular sieve adsorption towers. At room temperature, we introduce compressed air that has undergone filtration, dewatering, and drying into the adsorption tower. Inside the tower, nitrogen and other impurities are adsorbed by the molecular sieve, enriching the oxygen in the gas phase, which then exits through the oxygen buffer tank for storage. Meanwhile, the molecular sieve in the other tower, which has completed adsorption, undergoes rapid depressurization to release the adsorbed components. By alternating cycles between the two towers, we can consistently produce inexpensive oxygen of purity (93% ± 2).

Cryogenic Oxygen Generator

A technology that separates air through a deep freezing and distillation process to prepare oxygen. We actively cool the air to a temperature below 100 K in the deep freezing process to liquefy it. We then exploit the difference in boiling points of oxygen and nitrogen at atmospheric pressure—90 K for oxygen and 77 K for nitrogen—to make nitrogen, which has a lower boiling point, vaporize more readily than oxygen. In the distillation tower, the higher temperature of the vapor and the lower temperature of the liquid constantly in contact with each other, more nitrogen in the liquid evaporates, more oxygen in the gas condenses, so that the nitrogen content in the ascending vapors continues to improve, and the oxygen content in the downstream liquid continues to increase, in order to achieve the separation of the air, the production of high purity oxygen.

Electrolyzed water oxygen generator

The electrolyzer decomposes water into hydrogen and oxygen. During the electrolysis process, a power source provides electrical energy to break down water in the electrolyzer. We chemically perform the process known as water electrolysis, which results in the production of hydrogen and oxygen. We discharge hydrogen through a drainage unit and deliver oxygen to the required location through an air supply unit.

Oxygen Enriched Membrane Oxygen Generator

We utilize a special membrane material, known as an Oxygen Enriched Membrane, to actively separate oxygen from the air for the purpose of oxygen production. Oxygen-enriched membrane is a special membrane material with a high concentration of oxygen molecules inside, which can selectively allow oxygen to pass and prevent other gases from passing.

Oxygen generators of different types have different working principles, so after selecting the oxygen generator, you can choose according to the purity of oxygen, flow rate and application scenarios and so on. If the selection is difficult, you can contact us!

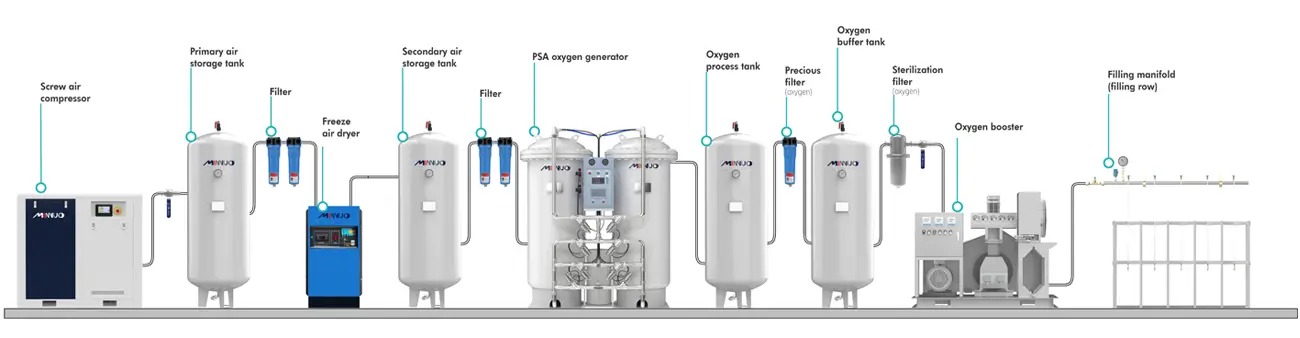

Oxygen Generator’s Main Components

Compressor: Compressor is one of the core components of the oxygen generator, the working principle of the compressor is to change the compression state of the gas by using the movement of the piston, and then use the characteristics of the gas elasticity to return to the gas, to compress the gas into a high-pressure gas.

Air filter: It is also one of the important components of the oxygen generator, the main role is to filter the impurities and moisture in the air to ensure the quality and purity of the oxygen produced by the oxygen generator. Commonly used air filters include CTAX four levels of filters. Each of these filters has different filtration functions, realizing the filtration of different particle sizes and different substances in the air.

Molecular sieve: made of zeolite and other crystalline materials, with a high degree of pore size precision and selective adsorption capacity, there are corresponding molecular sieve options for different gas components. We utilize the principle of adsorption based on molecular size differences to separate nitrogen and other impurities from the air, thereby achieving the goal of preparing pure oxygen.

Others are cooling system, control system and gas storage tank. The composition of different types of oxygen generators will have some differences, in the process of purchasing, you can contact our oxygen generator engineers to get professional technical support in order to purchase the right product.

Process Flow of Oxygen Generator Work

Compression: First, we actively draw air into the variable pressure adsorption oxygen generator and subsequently compress it. The pressure of the compressed air increases, but it still contains a large amount of nitrogen and a small amount of oxygen.

Adsorption: The compressed air enters the molecular sieve adsorption tower. We operate the molecular sieve adsorption tower under high pressure, where the molecular sieve selectively adsorbs oxygen from the air, leaving the nitrogen unadsorbed.

Pressure reduction: When the molecular sieve adsorption tower has adsorbed a certain amount of oxygen, we stop the air supply to the tower and begin reducing its pressure. During the pressure reduction process, we desorb the adsorbed oxygen, forming high purity oxygen.

Recovery: The desorbed oxygen goes through the recovery pipeline into the gas storage tank and is output as a product. Meanwhile, the pressure of the molecular sieve adsorption tower continues to decrease until it is close to atmospheric pressure.

Regeneration: We perform regeneration by reducing the pressure of the molecular sieve adsorption tower to near atmospheric pressure, which discharges the remaining nitrogen from the tower and regenerates the molecular sieve. During the regeneration process, the molecular sieve will absorb the oxygen in the new air, ready to enter the next cycle.

This cycle can realize the purpose of continuous oxygen production, so that users can choose the right oxygen generator for themselves at the same time can also improve the efficiency of oxygen production and reduce the cost of oxygen production.

Oxygen Generator Applications

Oxygen generators have a wide range of applications in a variety of fields, some of the main areas include:

1. Medical use: Oxygen generators are used in hospitals, clinics and home healthcare to provide high purity oxygen to patients. This oxygen is used in the treatment of respiratory diseases, surgery, first aid and oxygen therapy.

2. Industrial use: Oxygen generator is widely used in industrial process such as oxygen cutting, oxygen welding, ore smelting, oil refining, glass manufacturing and metal processing.

3. Food processing: Oxygen generator is used in food processing industry, such as in food packaging to prevent food from rotting and maintain the freshness of food.

4. Aquaculture, underground rivers, oceanariums: for fish and shrimp, aquatic products, aeration or mixing oxygenation

5. Wastewater treatment: oxygen-enriched aeration of activated sludge, pool oxygenation

6. Ozone generator: provide high concentration of oxygen electrolysis to produce ozone, ozone concentration is higher and more stable, disinfection and bleaching effect is better. Ozone water treatment is basically an oxygen source ozone generator ……

Minnuo Professional Oxygen Generator Manufacturer

Minnuo, focusing on improving the quality of oxygen generator, helps to help you realize the gas business and reasonably reduce your operation cost. We have a wide range of oxygen generator plants, such as PSA oxygen generator, cryogenic oxygen generator, VPSA oxygen generator, gas station, etc. If you want to know more, you can directly contact our sales engineers.

评论

发表评论